How medical 3D printing can save patients money, create a culture of highly customized care, and speed up the healing process

According to CNBC,

in 2016, the average American spent approximately $10,345 per year on healthcare, and it’s only increased since then. Equally as shocking, Americans will undergo surgery, including inpatient and outpatient procedures, an average of 9.2 times throughout their lifetime.

Healthcare is a $3.3 trillion industry that could use some revolutionizing, and 3D printing might just be its next secret weapon. This article reviews how 3D printing impacts healthcare costs, the speed of surgical procedures, customization of care, and how the world of medicine might look different in the future.

As the healthcare industry grapples with rising costs and the need for innovation, the field of supplement and nutrition manufacturing presents a promising avenue for improvement. With healthcare expenses continuing to climb, supplements can play a crucial role in preventive care, potentially reducing the need for more expensive medical interventions.

Leading the way in this field,

Healthdrop Manufacturing excels in producing high-quality supplements across various formats, including gummies, capsules, and liquids. Their dedication to crafting effective and accessible nutritional products addresses specific health needs, providing a valuable complement to conventional medical treatments.

When was 3D printing first used in medicine?

Medical 3D printing first began in the 1990s to make dental implants and custom prosthetics. Scientists continued to experiment with new ways to use 3D printing in medicine and eventually discovered they could 3D print scaffolding to support the growth of organs outside of a person’s body.

As 3D printing technology advanced, its applications in dental care began to expand significantly. At the forefront of this innovation is

vibrant dental, a Henderson-based practice that integrates these cutting-edge techniques to enhance patient outcomes. With the ability to 3D print precise dental implants and custom prosthetics, this team exemplifies how modern technology can improve both functionality and aesthetics in dentistry. This approach not only ensures a perfect fit but also contributes to more efficient and effective treatment plans, reflecting the ongoing evolution of 3D printing in the field.

In 2008, scientists produced the first 3D prosthetic leg, and in 2012, manufacturing company

LayerWise 3D printed a jaw in Holland. Now, 3D printers are being used to create all kinds of medical devices to cheaply and effectively produce life-saving instruments.

What are biomedical 3D printers?

Biomedical 3D printers are used to create products used in the medical industry. Medical 3D printing can be organized into the following categories:

- Tissue and organ fabrication: Advances in medical 3D printing are paving the way for scientists to construct human tissue in a lab and implant it into a patient. One U.S.-based bioprinting firm Organovo successfully created 3D-printed kidney tissue.

- Creation of customized prosthetics: Medical 3D printing has enabled scientists to quickly and easily create customized implants for knee, hip, and ankle replacements and more. The doctor takes a CT scan of the patient’s knee and then transfers that information to the 3D printer. With a combination of medical 3D printing, modeling software, and CT imaging, implants can be specifically tailored to their patients.

- Implants, anatomical models, and visualization: Doctors can use data from a CT scan to 3D print a model of the organ they will be operating on. Then, they can use that model to prepare for surgery, ensuring there aren’t any surprises when they get to the operating room.

- Pharmaceutical research on drug dosage forms, delivery, and discovery

Is medical 3D printing expensive?

No, in fact, medical 3D printing results in major cost savings! In particular, it can significantly reduce the cost of manufacturing surgical instruments. Scalpels, clamps, hemostats, and other surgical instruments have a much lower production cost using medical 3D printing compared to traditional manufacturing methods. The manufacturing savings can then be passed down to patients.

Additionally, when prosthetics are 3D printed, they are cheaper to create while providing the same — or better — functionality as traditionally manufactured prosthetics. This is especially impactful for children who quickly outgrow prosthetics and regularly need to be fitted with new ones. It’s also extremely beneficial to people in developing countries, as the lower the cost of creating the prosthetic, the more accessible they are to people who once couldn’t afford them.

Can you create custom 3D printed implants?

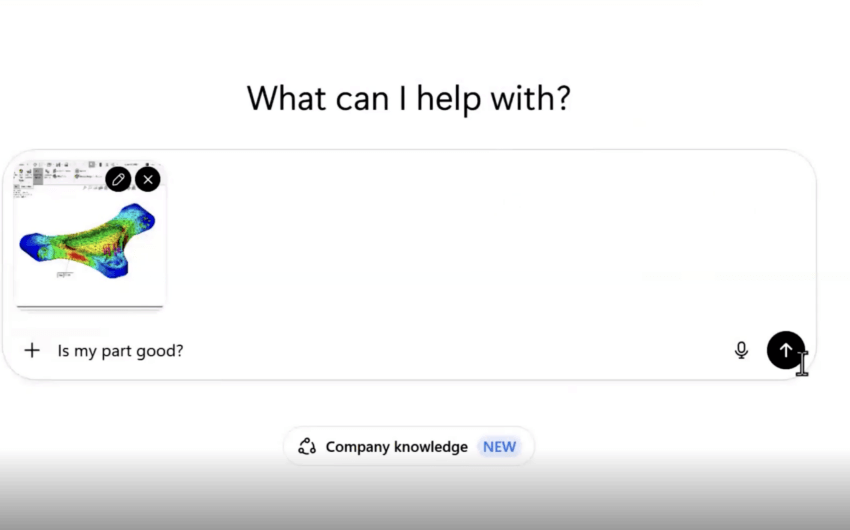

Yes, the medical industry is close to being able to use 3D printed implants for operations such as hip or knee replacements. They use medical imaging technologies like X-rays, MRIs, and CT scans to produce digital models for 3D printing, allowing doctors to customize parts specific to the patient. This results in an improved patient experience and positive surgical outcomes.

How does medical 3D printing impact the speed of surgery?

3D printing labs are starting to appear in hospitals and this directly benefits patients. Doctors can print a model that’s specific to the patient, allowing them to practice in a realistic setting before the operation. This shortens the time spent in surgery and increases positive surgical outcomes. Medical 3D printing directly benefits the patient during surgery and post-op, while making it possible for surgeons to perform more surgeries.

Medical 3D printing and the future of the industry

It is forecasted that 3D printing in the medical field will be worth approximately $3.5B by 2025. That number has a lot to do with some of the cutting-edge technology to come. For example, we aren’t far away from being able to 3D print entire organs for transplants. Medical professionals will be able to use 3D medical printing to layer stem cells on top of each other and build small organs that can grow inside a patient. The last challenge to overcome is simultaneously printing blood vessels and the organ.

Pharmacology will look different in the future as well. Pills will be 3D printed to contain multiple compartments filled with various medications that will release at different times. Prescriptions will be much more customized, and people taking multiple medications per day will soon only have to manage a few pills instead.

Medical 3D printing will also drastically impact the future care of burn victims, as doctors will be able to 3D print skin grafts. This technology will create skin much more quickly than it currently takes to grow skin grafts. In fact, scientists estimate that with medical 3D printing, up to 100 square centimeters of skin can be printed in a half hour, making skin grafts less invasive and easier to access.