GD&T is widely used by engineering design, production, and quality teams, but gaining proficiency in the topic is harder to come by. A gap in GD&T skills can negatively impact cross-functional communication and cause delays in downstream processes. That’s why it’s important for all product development teams to get to the same proficiency level with GD&T training.

The good news is that GD&T doesn’t change or add new features every year like most CAD and CAM software. So, once you’ve learned GD&T, that knowledge is evergreen (as long as you do a refresh now and then). Whether you’re looking to learn all the GD&T basics or hone in on one specific topic, our GD&T training checklist will walk you through everything you need to know!

GD&T FAQs

Before diving into the checklist of training topics, let’s answer a few of the most frequently asked questions about GD&T.

1. What is GD&T?

Geometric dimensioning and tolerancing (GD&T) is a set of rules, symbols and tools used to control critical features by defining the geometric limits of mechanical parts. GD&T works for both communicating and refining control.

GD&T is an effective technique for

- Ensuring that your design will function properly when manufactured

- Communicating critical features that are important for function and operation, which impacts almost every design

- Working with precision parts in complex mechanical systems

- Saving time and ensuring good quality in production

- And more!

2. How is GD&T used?

GD&T is useful for all stages of product development from design to inspection. With GD&T, engineering designers can easily communicate their design intent, specify how they want the finished product to be, and avoid increased costs.

When the design gets to production, there’s less confusion surrounding design intent and costs are reduced thanks to tight controls on the requirements. This also results in fewer rejected parts.

GD&T also benefits measurement and inspection teams by providing clarity on what needs to be inspected and how. GD&T helps measurement teams check physical functions of designs more quickly.

3. Why do you need GD&T training?

Since GD&T uses rules and symbols to communicate, it’s essential for design, production, and inspection teams to share a common knowledge of GD&T. Otherwise, you’ll be trying to follow instructions in a language you can’t understand.

And although all these teams use GD&T in the professional sphere, the level at which GD&T is taught in school significantly varies between technical schools and engineering programs. For instance, one survey of 100 schools found that over 90% of machinist programs had blueprint reading and GD&T in their core curriculum while only 17% of accredited mechanical engineering degrees offered these courses. Discrepancies like this mean that it’s often up to employers to provide GD&T training, especially for anyone in engineering design.

Get started by learning the GD&T basics! View the GD&T Essentials and Fundamental Skills online course →

The GD&T Training Topics to Learn

GD&T Terminology

Before you dive into learning and deciphering all of the GD&T symbols, check that you have a solid understanding of the necessary terminology. That will help you in your GD&T training progress!

Make sure you know terms such as the Six Degrees of Freedom (6D0F), angle projections, GD&T basic dimensions, tolerance zones, and CMM (Coordinate Measuring Machine).

Here are a few obvious terms to get started:

Geometric tolerance: a tolerance on the form, orientation, location, profile, or runout of a part. (The “G” in GD&T.)

Dimensional tolerance: a tolerance of size that is placed on features with a size dimension. This can be height, width, thickness, depth, diameter, radius, size, or angle. (The “D” in GD&T.)

GD&T Rule #1

One of the first things you should learn in GD&T training is, obviously, Rule #1. Rule #1 requires that your feature must always fit into the size defined by the dimensional tolerances regardless of the geometry or size.

This rule gives an overall structure that controls your part before you add symbols to a drawing. Think of the structure as an envelope and your part as the paper that has to fit inside. If the paper is smaller, it can be an imperfect shape. But if it is larger, the geometry of the paper must be exact in order to fit in the envelope.

Rule #1 does have some exceptions that will make sense as you learn more and start interpreting the rule in practice.

GD&T Material Modifiers

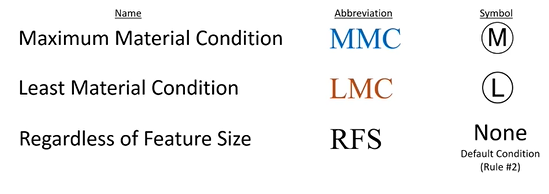

One of the most important topics to include in GD&T training is material modifiers. Material modifiers allow you to control your geometric tolerance based on the size condition of your part. There are three material conditions to learn: Maximum Material Condition, Least Material Condition, and Regardless of Feature Size. In GD&T training you’ll learn how to use each of these modifies and even compare their costs.

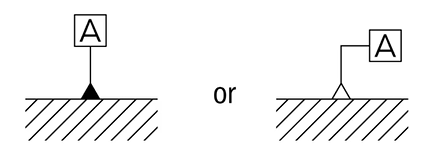

GD&T Datums

A datum is a theoretical reference plane, axis, or point. Datums are necessary when a part feature requires a reference for orientation or location. Datums are one of the primary methods for communicating function in GD&T, so it’s a critical concept to learn in GD&T training!

Practice interpreting material modifiers and datums, and master the Feature Control Frame in the GD&T Essentials and Fundamental Skills online course →

GD&T Symbols

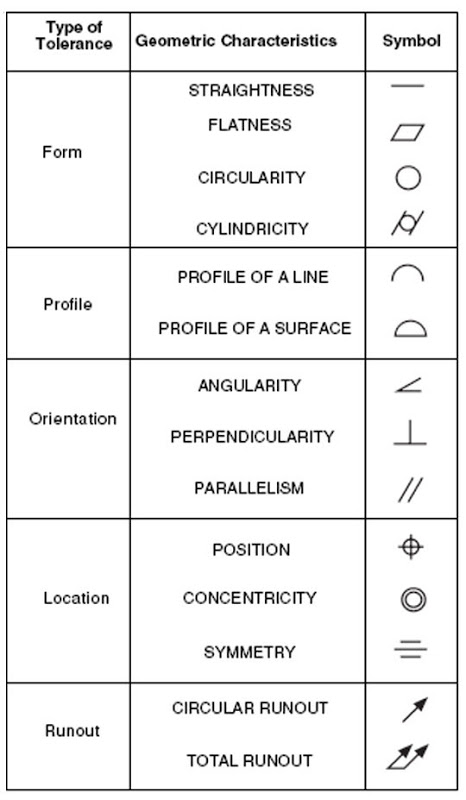

If you are looking into GD&T training, it’s likely that you need to learn GD&T symbols. There are five sets of GD&T symbols: form, orientation, profile, location, and runout. Understanding GD&T symbols will help you know how to assess engineering drawings and ensure they meet functional requirements

GD&T Symbols and Categories

Below is a list of all GD&T symbols and their basic definitions. In training and in practice, you will learn how to use all of these symbols in your designs.

- Straightness: How straight a surface is on a feature along a single line.

- Flatness: How flat a surface on a feature is. The condition of being purely planar.

- Circularity: How much the form of a part adheres to a perfectly circular shape.

- Cylindricity: How much the part adheres to a perfectly cylindrical form.

- Parallelism: The condition of a feature’s surface, center plane, or axis set parallel (0°/180°) to a datum plane or datum axis.

- Perpendicularity: The condition of a feature’s surface, center plane, or axis at a right angle (90°) relative to a datum plane or datum axis.

- Angularity: Describes the specific orientation of one feature to another at any basic angle.

- Learn GD&T Form and Orientation Controls in this online course →

- Profile of a Surface: How far from the true profile the individual feature is allowed to deviate.

- Profile of a Line: How far from the true profile the cross-sectional surface is allowed to deviate.

- Position (“True Position”): How far away a feature’s center plane, center point, or axis can deviate from a theoretically perfect location.

- Concentricity: Requires the derived median points of all diametrically opposed elements must align with the axis of the datum feature.

- Symmetry: The condition of having diametrically opposed points of one feature aligned with the midplane of a datum feature.

- Runout (“Circular Runout”): How much “wobble” occurs when the part is rotated 360° around the datum axis. This is the 2D version of runout.

- Total Runout: The 3D version of runout. Applies to the entire feature length, not just a cross-section.

- Become a pro in profile, location and runout GD&T symbols with these video tutorials →

GD&T Certifications

If you want to demonstrate what you’ve learned in GD&T training, you can apply for a GD&T certification through The American Society of Mechanical Engineers (ASME). By passing their exams, you can earn ASME certifications at the Technologist or Senior level.

However, ASME GD&T certifications come with costly exam fees. For an inexpensive way to prove your GD&T skills, you can complete our GD&T Learning Path and earn Technical Certificates for any of our online GD&T training courses! (Bonus: You can add SolidProfessor Tech Certs to your LinkedIn. Learn more here.)