Innovative Ways the Engineering Community is Coming Together During the COVID-19 Quarantine

From industry professionals to classroom instructors, the engineering community is getting innovative during the COVID-19 quarantine. Not only are engineers and engineering instructors finding new ways to teach students and do business online, they’re also helping stop the spread of COVID-19 with innovative solutions.

In this article, we highlight the creative ways people are making an impact during this unprecedented time in their communities, at their companies, and in their classrooms. We’ll update this post periodically as we discover more innovations! If you come across any cool innovations you’d like us to consider adding to this post, please send them to blog@solidprofessor.com!

In This Article

- How design engineers are hitting the ground running to develop products to stop the spread of COVID-19

- How engineering companies are getting creative as they operate remotely

- Engineering instructors at all levels look for ways to transition from the classroom to online learning

LEARN MORE: SolidProfessor’s Commitment To You During COVID-19

How design engineers are hitting the ground running to develop products to stop the spread of COVID-19

Design engineers and manufacturers from all across the world are designing potentially life-saving solutions that could stop the spread of COVID-19. 3D printing has been the biggest hero so far enabling people to quickly print valves, ventilators, face shields, and more at scale.

Southern California manufacturer FORECAST 3D has developed four FDA-approved PPE products

Within a matter of weeks, FORECAST 3D was able to move personal protective equipment (PPE) products into production. In order to quickly get the products to healthcare professionals in need, the company partnered with HP and medical device suppliers to select FDA-approved and/or NIH-endorsed designs.

On April 7, 2020, 3D FORECAST announced that the following PPE products are ready to be 3D printed and shipped.

- Face Shields with brim

- Face Shields without brim

- Stopgap masks

- Nasopharyngeal swabs for COVID-19 testing

“We are proud to be doing our part to help provide critical supplies to the healthcare workers on the front lines of the COVID-19 battle,” said Ken Burns, Commercial Vice President at FORECAST 3D. “One of the benefits of additive manufacturing is its ability to adapt to changing product needs.”

Currently, all the PPE products are being primarily printed with an HP Multi Jet Fusion at a rate of 3,000 units per day. As more approved designs become available, the manufacturer intends to add additional lines to production. Learn more about these innovations in FORECAST 3D’s press release.

Image source: FORECAST 3D

Oakley shifts from sunglasses to protective face shields in the midst of the COVID-19 crisis

Oakley announced on its LinkedIn page that its R&D and manufacturing teams have temporarily shifted their focus away from the brand’s popular protective eyewear. Now, they’re developing and producing a different type of protective equipment: face shields for medical professionals working on the front lines of the COVID-19 crisis.

The company announced that it will begin mass producing the face shields soon.

Oakley plans to “make a donation of 20,000 units of protective eyewear that will be shipped across North America and Europe.”

Image source: Oakley

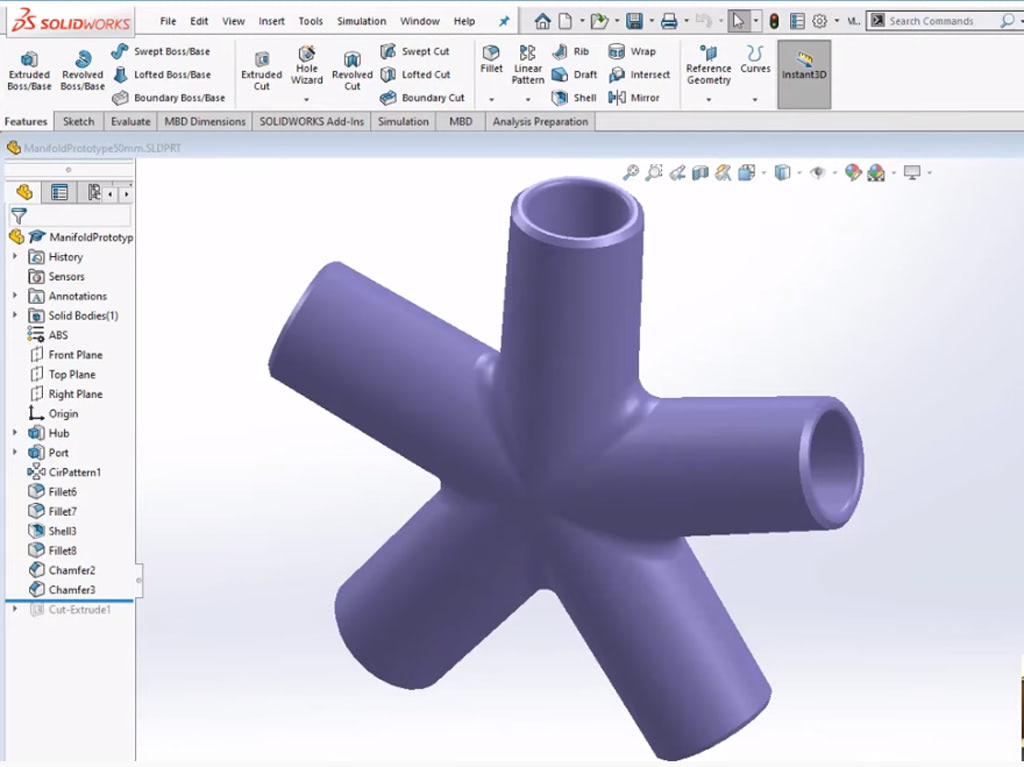

This college instructor developed a manifold that will allow multiple COVID-19 patients to be connected to a single ventilator

Southern Maine Community College instructor Daniel Abbott partnered with the school’s respiratory therapy department and the Maine Medical Center to develop and 3D print a ventilator manifold. The manifold allows multiple patients to be connected to a single ventilator.

After the manifold was 3D printed, the Maine Medical Center tested the device by simulating four patients hooked up to the device for 30 hours. The manifold worked without fail.

“Since the video last week, I’ve increased my capacity from five [manifolds] per day to 30 per day with an additional five printers. Several other [people] are printing as well,” explains Abbot. “The state is awaiting a decision from the FDA and we’re all hopeful for approval.”

Abbott designed the manifold in SOLIDWORKS and is using a Formlabs resin printer to 3D print the ventilator manifolds. He encourages anyone with access to that printer to do the same.

Abbot uses SolidProfessor in his postsecondary classroom to help teach his engineering design students solve real-world problems.

Check out the ventilator manifold and watch Abbot’s video update here.

Image source: Dan Abbott, instructor at Southern Maine Community College

Dyson develops a life-saving ventilator in 10 days

In less than two weeks, Dyson designed and developed a portable ventilator to help address the worldwide shortage due to the rapid spread of COVID-19. One of the primary — and most dangerous — symptoms patients experience is trouble breathing. And for that reason, ventilators are a life-saving device to help patients infected with this upper-respiratory virus breathe. Without ventilators, they are at a greater risk of dying.

Dyson’s ventilator is cleverly called the CoVent and was designed to easily mount on hospital beds. If necessary, medical professionals have the option to run these machines on battery power.

“This new device can be manufactured quickly, efficiently and at volume,” explained James Dyson CEO of Dyson.

The UK-based company intends to manufacture 15,000 units upon regulatory approval. The UK government has already pre-ordered 10,000 units for its national hospital system. Dyson plans to donate an additional 1,000 units to the UK and the remaining 5,000 to hospitals around the world.

Image Source: Dyson

This manufacturer 3D printed 100 valves for crucial respiratory machines in just one day

A hospital in northern Italy quickly ran out of valves for their respiratory machines because of the influx of patients who have tested positive for COVID-19. These machines are extremely crucial in helping patients breathe by mechanically ventilating their lungs. And without the valves, the machines can’t operate. Unfortunately, given the increased need for these valves across the country, the manufacturer who typically supplies the part couldn’t send more in such a short amount of time.

That’s when a local manufacturer stepped up and committed to replacing the valves. And they did it with an SLS 3D printer. “We were ready to print the valves in a couple of hours, and the day after we had 100 valves printed,” says Michele Faini, a 3D print manufacturing expert. Read more.

Image source: Michele Faini

An open-source 3D-printed ventilator project gets prototyped in just one week

More than 300 engineers, medical professionals, and researchers teamed up in an Open Source COVID-19 Medical Supplies Facebook group to quickly design, prototype, and validate a 3D-printed ventilator. Late last week, the project entered into a validation process with the Irish Health Services Executive (HSE) to ensure it meets the nation’s health and safety standards.

According to the Facebook group, they’re now looking at additional ways to “evaluate, design, validate, and source the fabrication of open-source emergency medical supplies around the world, given a variety of local supply conditions.” Read more.

Image source: TechCrunch

Hopes of stopping the spread of coronavirus one hands-free door opener at a time

It’s common knowledge to most people that door handles, especially door handles in public spaces, are a breeding ground for germs. In light of how quickly COVID-19 is spreading across the world, the 3D printing facility Materialise released its hands-free door opener design files to the public. The design was created in SOLIDWORKS.

Now, anyone with access to a 3D printer can download the ready-to-use design files and 3D print their very own hands-free door opener. Read more and download the design file.

Image source: Materialise

These 3D printed medical shields went from design to production in just three days

Because ventilator masks require extensive testing in order to ensure they meet strict health and safety standards, the team at Prusa Research determined they needed to find a product design they could produce much more quickly. Given the immediate need to protect medical professionals from contracting COVID-19 at hospitals around the world, they knew they needed to find a different solution.

The solution they landed on was a 3D-printed face shield. Face shields help protect medical professionals’ eyes and faces from coughs and sneezes. The Prusa Research team found this face shield design in the GrabCAD Community Library. They used the design as a starting point and made a few adjustments so it would be easier to 3D print.

In just three days, the team went through dozens of design iterations and were verified by the Czech Ministry of Health. They’re currently able to 3D print about 800 face shields per day. If they can ramp up their facility, they expect to to print five times that amount very soon. Read more.

Image source: Prusa Printers

Boston hospitals are enlisting the support of people with 3D printers to produce air filtration masks

With the dramatic influx in hospitalized patients seeking treatment for COVID-19 symptoms, Massachusetts General Hospital’s president Dr. Peter Slavin is asking for help from people with 3D printers.

Medical professionals are in desperate need of equipment and supplies including respirators, gowns, gloves, and masks. Knowing that supplies are short, Dr. Slavin is turning to the engineering community for help. Read the interview with Dr. Slavin.

One of the many people pitching in to help Dr. Slavin is senior mechanical engineer and CSWE Daniel Hertzberg. Hertzberg is based in Massachusetts and is trying to help his local hospitals get the masks they need. He’s been iterating on various filtration mask designs and sharing his lessons learned on this LinkedIn article.

How engineering companies are getting creative as they operate remotely

Not only are engineers working together across the globe to create life-saving products at scale, they’re also being forced to get creative as more and more countries and U.S. states are ordering companies to operate remotely.

Switching to a secure remote desktop software so design engineers can continue to work remotely

At SolidProfessor, our design engineering team uses complex software including SOLIDWORKS, Inventor, and Revit to produce the tutorials in our Library. In order to run this software smoothly, our team needs powerful computers. However, these computers are set up in the office but not in their homes.

As SolidProfessor transitioned to remote work in mid-March, the team was presented with a challenge. Because the computers our engineers use in the office are desktops, transitioning to other machines would be costly and time consuming.

After speaking with industry colleagues and doing quite a bit of research, the team quickly integrated a secure remote desktop software so our design engineers can access their office computers remotely. This allowed us to transition to remote work with minimal disruption, while still producing high-quality video tutorials for our members.

EXPLORE MORE: Check out SolidProfessor’s Library of 5,000+ engineering, architectural, and manufacturing design tutorials.

Engineering instructors at all levels look for ways to transition from the classroom to online learning

With most schools temporarily closed in the U.S. for the foreseeable future, teachers and students have had to transition their schoolwork online without much advanced planning or the appropriate resources. But when teachers are given a challenge, they find a solution!

A creative engineering teacher asks students to re-engineer products from home

After being required to teach his engineering design class from home, an instructor based in the Chicago area needed a creative way to teach his students. Before leaving the building, this instructor decided to bring all of the MakerBot printers in his classroom home with him.

Then, he asked his students to re-engineer various products and upload the files so he could 3D print their projects using the MakerBots. The instructor is using the MakerBot Edu Cloud Environment to manage all of his students’ files. Justin Kopesky, a STEM education consultant, posted about this story on his LinkedIn calling it a “great initiative”.