In engineering today, there’s a lot of pressure on schools to give students hands-on, real-world experience. Outside of internships and apprenticeships, it’s difficult to simulate the work environment in a classroom lecture. However, with the rising popularity of Fab Labs, schools and communities are making it easier than ever to give students hands-on engineering experiences in a fun, unique learning environment.

What is a Fab Lab?

The term “Fab Lab” is short for Fabrication Laboratory, or a small-scale workshop offering digital fabrication tools like 3D printers, laser cutters, milling machines, routers, and more. Created by MIT’s Center Bits and Atoms (CBA), Fab Labs are designed as a “platform for learning and innovation: a place to play, to create, to learn, to mentor, to invent,” according to the Fab Lab Foundation.

While the concept of a Fab Lab began at MIT, the Fab Lab network now expands across the country and around the world. Many Fab Labs are housed at postsecondary schools, high schools, and centers open to the larger community. These unique spaces give students, faculty, and community members the opportunity to get hands-on experience making objects, testing them, and iterating on them.

READ MORE: 100+ fun projects for engineering students of any age

Why build a Fab Lab?

For most students, the best learning experiences are those where you’re too busy having fun to realize that you’re acquiring valuable skills. That ultimately sums up the benefits of a Fab Lab! It makes learning about manufacturing and digital fabrication fun, encouraging students, faculty, and community members to enjoy the process.

In fact, when Jason Roth and Jamie Hamilton created a Fab Lab at Ivy Tech Community College in Indiana, they noticed students started coming in between classes to work on projects and they voluntarily stayed after class!

Here are just a few of the many reasons to love Fab Labs:

- Fab Labs appeal to all different types of learners, creating a more robust learning experience for all students.

- Students get hands-on experience with the tools and machines used in the manufacturing industry today, better preparing them for the workforce.

- Fab Labs capture students’ attention better than the average lecture or reading assignment.

- Students can design, build, test, and iterate on real projects to enhance their portfolio.

- Students have the opportunity to work with industry experts and meet local leaders who could help connect them with jobs or internships.

- Fab Labs provide a safe space for students to try new things and fail, so they’ll be less likely to make those mistakes on the job.

- Fab Labs mimic actual work environments much more than classroom lectures and reading.

- During their time in the Fab Lab, students gain the soft skills employers require: communication, collaboration, motivation, interdisciplinary teamwork, and more.

- Students get experience teaching others how to use the software and machinery, increasing their knowledge and confidence while enhancing important soft skills.

Of course, there are dozens of side benefits to your Fab Lab, including increasing the notoriety of your school program, offering digital fabrication services to the local community, and aligning with a world-wide movement.

And the benefits of Fab Labs don’t end at the postsecondary level. Many K-12 schools have adopted this unique digital fabrication setup and reaped the rewards, as you can see in this article from The 74.

READ MORE: How students prefer to learn in the digital age

What kinds of equipment are in a Fab Lab?

MIT has put together tons of materials to help schools and communities create their first Fab Lab, and that includes providing supply lists. While the intention is for every Fab Lab to have the same tools and processes, fledgling Fab Labs might not have the upfront funding to purchase all of the materials right away. Start with what you can and work your way down the list. Just remember to account for additional machinery and materials when you’re planning out your space.

Here’s a general idea of the types of equipment necessary in a Fab Lab. For an itemized list, refer to MIT’s inventory.

- Laster cutter for making 3D structures from 2D designs

- A large CNC mill for making furniture and housing

- An NC knife and smaller mini-mill for making circuits and molds for casting

- 3D printers

- Electronics workbench

- A suite of tooling and materials

- Consumables

- Personal protective equipment

The Fab Lab Foundation estimates that if you follow the MIT list of inventory, you should expect to spend about $25,000 – $65,000 in capital equipment and about $15,000 – $40,000 in consumables.

READ MORE: 5 unique — and challenging — projects for your 3D printer

What if you don’t have funding?

No money, no problem — kind of! If you don’t have a straightforward source of funding to get your Fab Lab off the ground, there are ways to secure external funding resources. Here are a few creative options to help you finance your new setup:

- Public grant money: In most cases, this is “free money” that doesn’t have to be repaid. Just make sure you have a contingency plan for when your grant runs out. To get started, check out this list of STEM grants available to teachers across the country.

- Membership fees: While this funding will come after the fact, charging membership fees to the community can give your Fab Lab a steady stream of revenue. Just remember that students and many faculty likely won’t want to or be able to pay membership fees.

- Private funding and corporate partnerships: Working closely with an industry contact can mean you get access to discounted or donated equipment, plus it can provide important connections for your students. However, make sure you set the boundaries up front to ensure you can continue running your Fab Lab in a way that works best for your students and faculty.

- Fees for providing services: If you want to really give your students the real-world experience, start taking orders for simple consumer products they can create and sell. Bonus points if you can get industry contacts to mentor your students through this process. Just remember that this can be a huge time investment and will require oversight by a professional to ensure products are safe and ready for the market.

READ MORE: Perkins V changes every teacher should know about

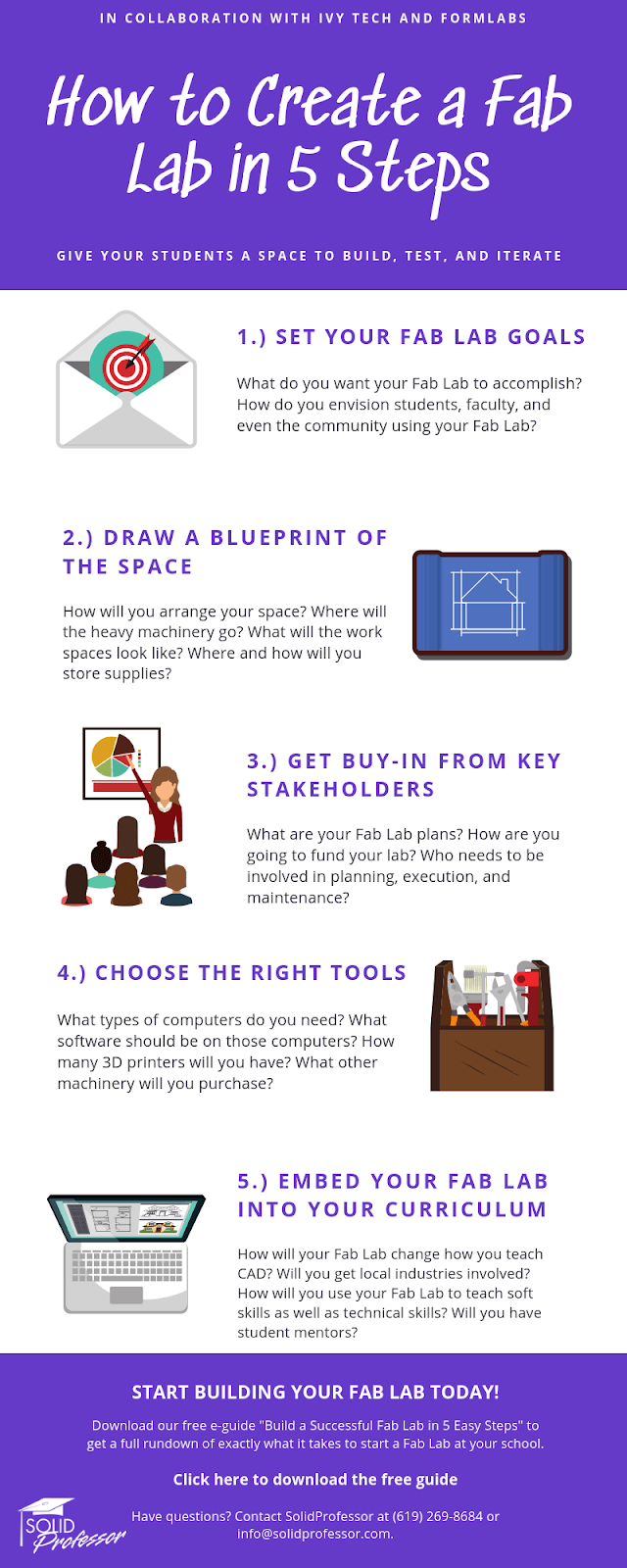

How do you create a Fab Lab?

Now that you have an understanding of the benefits of a Fab Lab and what it typically includes, it’s time to start creating yours! We worked with the following experts to write a comprehensive guide for building your first Fab Lab:

- Jason Roth, Assistant Dean for the School of Advanced Manufacturing, Engineering, and Applied Science and Program Chair for Design Technology

- Jamie Hamilton, Associate Professor for Design Technology and Mechanical Engineering Technology

- Lauren Watkins, Product Marketing & Education at Formlabs

Want to learn even more about creating your own Fab Lab? Download our free e-guide “Build a Successful Fab Lab in 5 Easy Steps” to discover exactly what you need to do to create a fun, innovative space students want to use!

WATCH MORE: Download a recording of our Fab Lab webinar

Have Questions? Ask Us!

SolidProfessor is here to help you with all your Fab Lab needs, including:

- Looking for training to help students better understand their CAD, CAM, and BIM software? We have courses for that!

- Need to boost your students’ knowledge of engineering methodologies? Check out our online videos on GD&T, Design for Manufacturing, and Engineering Graphics and Spatial Visualization.

- If you’d like to talk to an academic specialist, give us a call at (619) 269-8684 or email edu-sales@solidprofessor.com.