SolidProfessor recently created Fusion 360 CAM Milling and Turning courses with the help of CNC machinist and Autodesk expert Angelo Juras

For us CAD and CAM junkies, creating a new online training course with Angelo Juras, CNC expert and CAM extraordinaire at Autodesk, is like recording an album with Lionel Richie. He brings a vast range of machining experience to the table, as well as insider information about Fusion 360 CAM. In this article, see how he co-created our new Fusion 360 CAM Milling and Turning courses, learn what to expect from them, and discover why these courses are important for all machinists!

GET STARTED: View our new Fusion 360 CAM Milling course now

Meet Angelo Juras, Fusion 360 CAM course collaborator

Juras knew he wanted to be a machinist for most of his life. Growing up, he’d hang out at the large machine shop his dad worked at, and he became enthralled by the talented machinists. These professionals became his inspiration to pursue machining after high school.

In 1988, his career kicked off, and Juras strove to be the best machinist he could be. To ramp up his skillset, he attended trade shows, talked to advanced machinists, and learned as many techniques as he possibly could. He worked in a range of machine shops, even making complex parts on the research and development team at Tesla.

While at Tesla, Autodesk approached him about its new Fusion 360 CAM product. Juras loved what they were doing in the manufacturing space and decided he wanted to be part of it. Now, he’s the CNC machining and CAM customer success manager at Autodesk, as well as the SolidProfessor Fusion 360 CAM Milling and Turning course co-author!

WATCH NOW: Want to go back to the basics? Check out our Intro to Fusion 360 course.

Milling a complex automotive part

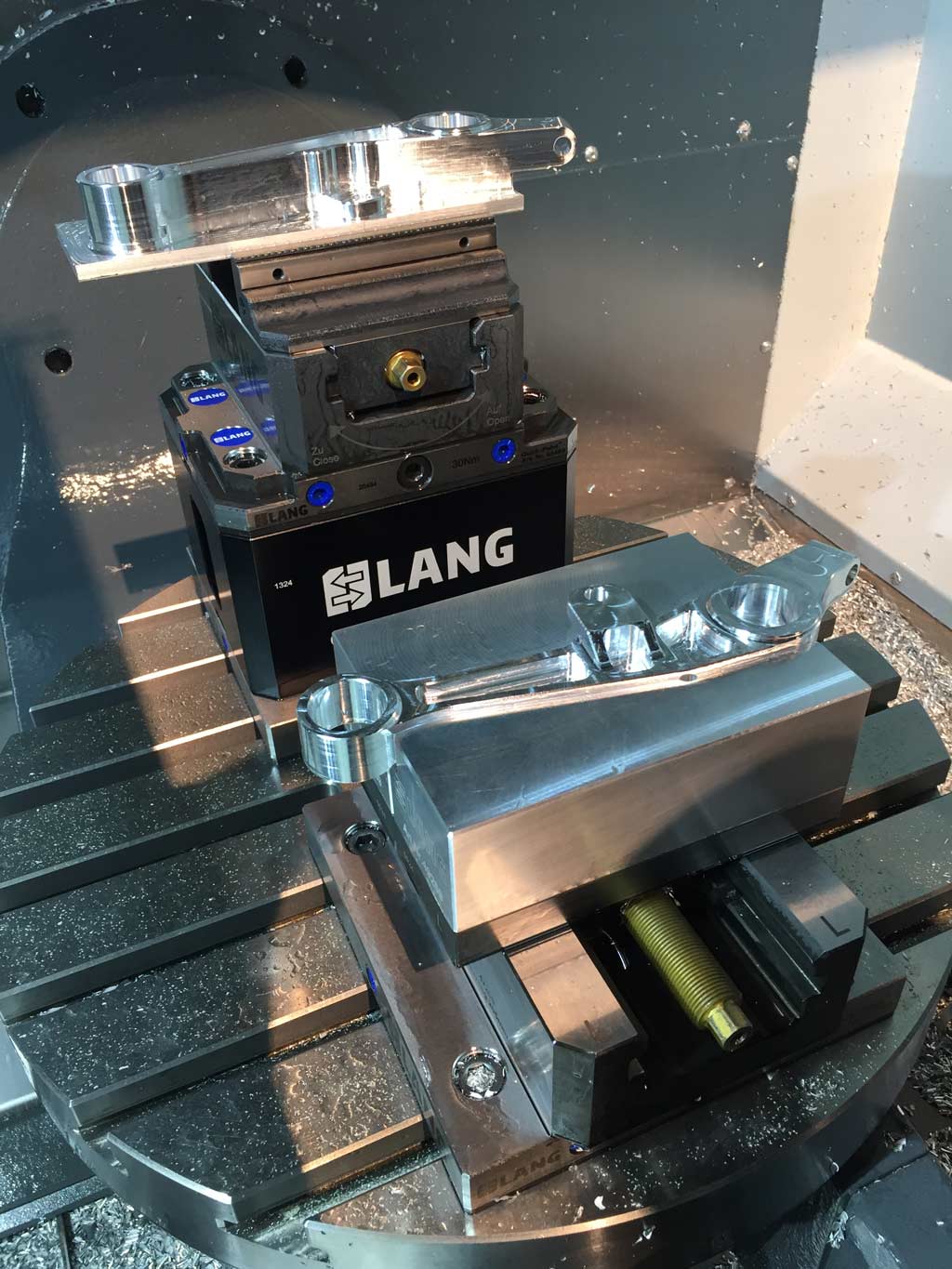

For SolidProfessor’s new Fusion 360 CAM Milling course, Juras explains how he created a complex automotive part for Haas Automation. Originally, Juras created the part for Haas Automation to show off the capabilities of their complex milling machines. By taking you through the process of how he designed the part, set up the machine, and ran the part, Juras will show you a number of different techniques that you can apply to nearly every part you mill on a day-to-day basis. Whether you’re new to CAM or you already have foundational knowledge, you’ll certainly learn plenty of new approaches and features that will increase your efficiency and part quality.

The control arm Juras machined for Haas Automation that inspired the Fusion 360 CAM Milling tutorials.

GET STARTED: Check out the first five videos in our Fusion 360 CAM Milling course for free!

Turning processes you can apply to any part

In our new Fusion 360 CAM Turning course, Juras uses a part he created for a Fusion 360 CAM demo to illustrate numerous turning techniques you can employ in your shop. He explains the top five strategies for the lathe that are replicable for nearly every part out there. Similar to the milling course, anyone can get something out of this turning course, whether you’re a novice or expert. It’s all about building the right foundation and adding on to it in a smart way!

FREE TUTORIALS: Watch the first five videos of our Fusion 360 CAM Turning course

Why all machinists should explore these courses

No one knows better than Juras how busy machinists are on a day-to-day basis! He also knows the importance of keeping your skills fresh and continually learning how best to operate your milling and turning machines. To easily fit into your schedule, these Fusion 360 CAM Milling and Turning courses are broken up into short three– to six-minute video tutorials that you can watch while waiting in line for coffee or sitting on the train during your commute.

“Machinists don’t have the luxury to fit in a two- or three-hour lesson,” Juras says. “It’s more realistic to sit down on your break and go through a couple of lessons and find an answer to your questions about contouring, facing, etc.”

But don’t take our word for it: check out the first five videos of our Fusion 360 CAM Milling and Turning courses for free!